In the realm of industrial applications, the quest for materials that exhibit unparalleled durability, strength, and versatility is ceaseless. Among the myriad options available, tungsten carbide plates emerge as a standout choice, revered for their exceptional properties and wide-ranging utility across various industries. In this comprehensive exploration, we delve into the remarkable benefits of tungsten carbide plates and their invaluable contributions to industrial processes worldwide.

Understanding Tungsten Carbide Plates

Tungsten carbide, a compound comprising tungsten and carbon atoms, stands as a testament to human ingenuity and scientific innovation. Renowned for its remarkable hardness, heat resistance, and wear resistance, tungsten carbide has cemented its status as a quintessential material in the realm of industrial engineering.

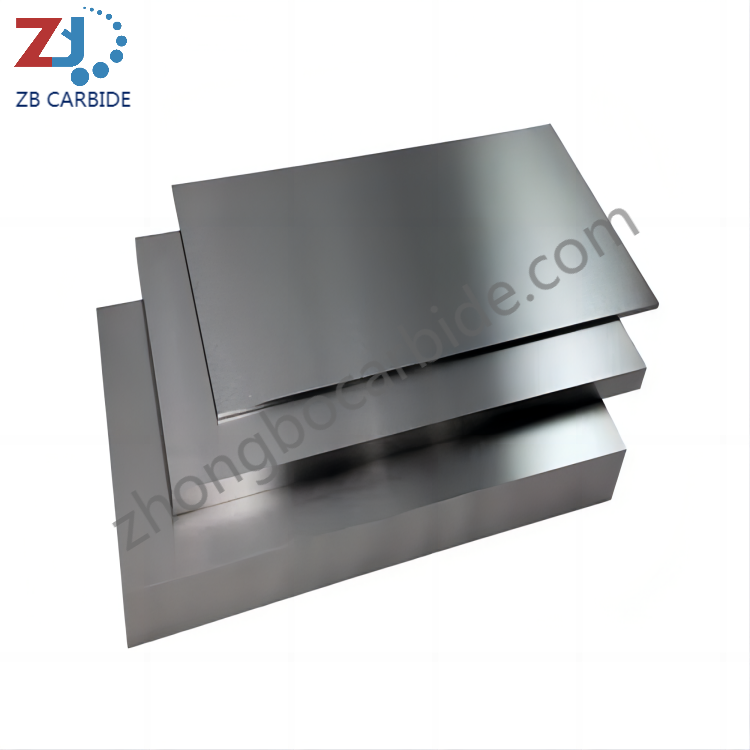

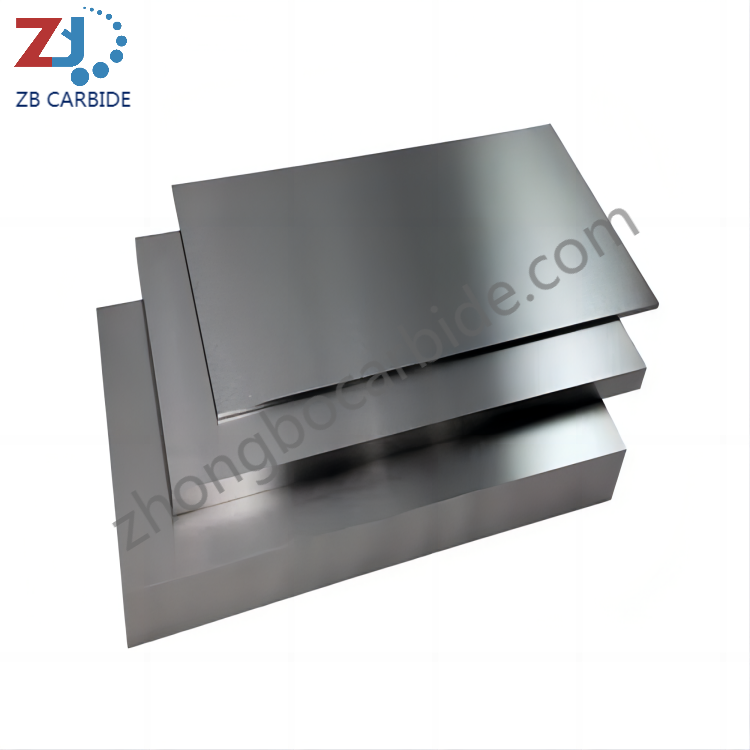

Tungsten carbide plates, crafted through a meticulous process of sintering tungsten carbide powder with a binding agent such as cobalt, embody the epitome of strength and durability. These plates, available in a myriad of shapes and sizes, find extensive applications across diverse industries, ranging from manufacturing and machining to mining and construction.

The Advantages of Tungsten Carbide Plates

●Unmatched Hardness: Tungsten carbide plates boast an extraordinary hardness that surpasses that of traditional metals such as steel. This exceptional hardness renders them highly resistant to abrasion, making them ideal for applications where wear and tear are prevalent.

●Wear Resistance: In industrial settings characterized by harsh operating conditions and abrasive environments, wear resistance is paramount. Tungsten carbide plates excel in this regard, exhibiting unparalleled resistance to abrasion, erosion, and corrosion. As a result, they maintain their structural integrity and performance over prolonged periods, minimizing downtime and maintenance costs.

●Exceptional Strength-to-Weight Ratio: Despite their formidable hardness, tungsten carbide plates possess a remarkable strength-to-weight ratio, surpassing that of traditional metals. This unique combination of strength and lightness makes them well-suited for applications where weight reduction is desired without compromising on structural integrity.

●High Temperature Resistance: Industrial processes often entail exposure to extreme temperatures, necessitating materials capable of withstanding thermal stress. Tungsten carbide plates, characterized by their high melting point and thermal stability, exhibit exceptional resistance to heat, ensuring reliable performance even in the harshest operating conditions.

●Precision Machining Capabilities: Tungsten carbide plates lend themselves to precision machining with unparalleled ease and accuracy. Their inherent hardness allows for intricate shaping and machining, enabling the creation of intricate components and parts with utmost precision and consistency.

●Versatility Across Industries: From cutting tools and wear parts to dies and molds, tungsten carbide plates find a myriad of applications across diverse industries. Whether in automotive manufacturing, aerospace engineering, or oil and gas exploration, these plates play a pivotal role in enhancing efficiency, productivity, and reliability across various industrial processes.

●Cost-Effectiveness: While tungsten carbide plates may entail a higher initial investment compared to conventional materials, their longevity and durability translate to significant cost savings in the long run. By minimizing downtime, reducing maintenance costs, and extending the lifespan of industrial components, these plates offer a compelling return on investment for businesses seeking to optimize operational efficiency.

Applications of Tungsten Carbide Plates

●Cutting and Milling Tools: Tungsten carbide plates serve as the backbone of cutting and milling tools used in metalworking, woodworking, and machining applications. Their exceptional hardness and wear resistance make them indispensable for achieving precise cuts, high-quality finishes, and extended tool life.

●Wear Parts and Components: In industries where abrasion and wear are prevalent, such as mining, construction, and manufacturing, tungsten carbide plates find extensive use in wear parts and components. From drill bits and cutting edges to crusher liners and conveyor belts, these plates ensure optimal performance and longevity in demanding environments.

●Die and Mold Manufacturing: The hardness and precision machinability of tungsten carbide plates make them indispensable for die and mold manufacturing in the plastics, automotive, and electronics industries. Whether for injection molding, extrusion, or stamping, these plates facilitate the production of complex and high-precision components with exceptional repeatability and accuracy.

●Oil and Gas Exploration: In the oil and gas industry, where drilling operations are conducted in challenging geological formations, tungsten carbide plates play a crucial role in drill bits and downhole tools. Their superior hardness and wear resistance enable efficient drilling through rock, shale, and other formations, thereby enhancing drilling performance and productivity.

Conclusion

In conclusion, the benefits of tungsten carbide plates for industrial applications are unequivocal. From their unmatched hardness and wear resistance to their exceptional strength-to-weight ratio and precision machining capabilities, these plates embody the pinnacle of engineering excellence. As indispensable components in cutting tools, wear parts, dies, molds, and drilling equipment, tungsten carbide plates play a pivotal role in enhancing efficiency, productivity, and reliability across diverse industries worldwide. As industries continue to push the boundaries of innovation and technological advancement, the demand for tungsten carbide plates is poised to soar, driving progress and prosperity in the global industrial landscape.