When winter comes, some areas may suffer from huge snowing, such as Canada, America, Norway, Finland and so on. The roads may be blocked by snow, and then a snowplow car would come and help clean the snow. A snowplow or snow plow is specifically used for removing snow and ice to guarantee the safety of people and cars on the road. By utilizing a carbide snowplow blade or carbide cutting edge. A snowplow can effectively push snow and ice to the roadside, thus clearing the road surface. Several types of cemented carbide snow plow blades we can use are manufactured from different hardness and designed for working on different types of situation. They can be made from tungsten carbide different grade for different temperature. Manufacturers can also design different types of carbide snow shovels by using different equipment.

Though looking similar to a steel snow plow blade, a carbide snow plow blade has a carbide insert brazed into the steel. Carbide-cutting edges are ideal for removing ice and deep snow thanks to their sharpness. Compared to blades made of just steel, carbide snow plow blades are more expensive, but feature excellent wear resistance. As we know, tungsten carbide is an extremely hard material but can easily break, so we need a steel cover to protect the carbide insert. Besides, carbide cutting edges also have excellent corrosion resistance. Though carbide snowplow blades cost more than traditional steel cutting edges, they are much more durable and don’t need to be replaced frequently.

The tungsten carbide insert, always we call tungsten carbide buttons, is a cylinder tool with a round or sharp head. Except for snow plowing, it can also be used in mining, oil, and construction. For different applications and working conditions, tungsten carbide buttons may be different in the binder content, size, shape, and so on.

Carbide grader blades are designed for high abrasion, low impact applications where maximum wear life is desired. These cutting edges consist of a tungsten carbide insert and overlay to increase the wear life of the blade many times longer than conventional steel blades. These edges do come at a higher price than a steel edge; but when properly operated, the cost and time savings will give a great return on the investment.

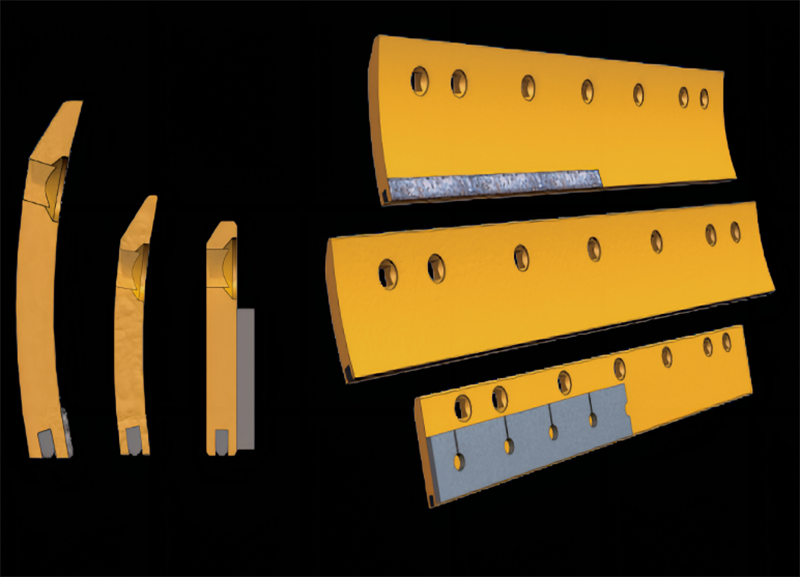

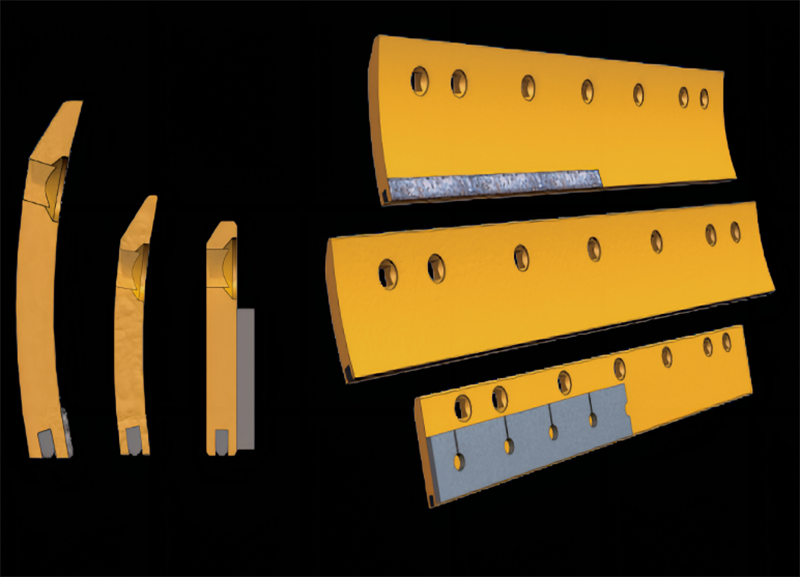

Carbide grader blades look similar to standard steel grader blades, but they have a carbide insert brazed into the thickness of the edge and some offer an overlay along the bottom of the blade. Carbide is an effective way to increase the wear life of your blades and decrease the time and effort of changing blades. ZHONGBO CARBIDE COMPANY offers our high-quality carbide grader blades with a variety of options. There are three main styles:

Double carbide curved blades with a top bevel, carbide insert, and carbide impregnation.

Pick carbide inserts with a carbide overlay for wear resistance and face protection.

Flat face carbide insert with carbide plate overlay for wear resistance and face protection.

Carbide snow plow blades are a widely used type of snow plow blade. They are a natural progression from standard steel snow plow edges which were discussed in the first post of this series: Snow Plow Cutting Edges – An Introduction to Steel.

ZHONGBO CARBIDE CO., LTD has experts in all aspects of ground engagement edges, blades, and tools. We are doing this educational introduction series to share some of our knowledge with operators so that they can be more efficient and reduce their overhead costs.

To begin, it is important to give a brief overview of this particular snow plow cutting edge style. Carbide snow plow edges are used on the front, underbody, and wing of a snow plow. Carbide snow plow blades look very similar to traditional steel edges; however, they have a carbide insert brazed into the thickness of the steel face along the bottom of the blade. This carbide insert has much better wear resistance properties than a cutting edge made of just steel. This gives the operator the following benefits:

Longer Wear Life – on average carbide cutting edges have 3-5x more wear lifespan than heat-treated steel edges, and up to 20x more when compared to Carbon Steel

Even Wear – carbide snow plow cutting edges will wear evenly across the face of the blade, which can help reduce the “crowning” effect that many operators experience with steel edges.

Saves Time – Because the blades last longer and wear more evenly, operators can spend less time changing blades and more time out on the roads pushing snow.

ZHONGBO take OEM part numbers and add carbide to areas of the parts that wear prematurely.Adding carbide to blades has proven to greatly extend the wear life - approximately 8 to 10 times that of a standard through hardened edge. ZHONGBO offers custom carbide options to improve the wear life in any application, including carbide impregnation, hard-faced shield, and double carbide inserts.These options are also available for carbide underbody blades, carbide underbelly blades, carbide snow pusher blades, carbide box scraper blades, carbide sectional snow plows, carbide Western plow blades, carbide Boss plow blades, and many others.

Carbide Grader Blades are a superior choice for any low impact, high abrasion application. The inserted carbide teamed with abrasive

resistant carbide insert/carbide impregnated significantly extends the life of the parent material when used in applications where "face" wear is a problem. Tungsten carbide inserts result in a carbide grader blade

that will have extremely long wear life. This allows for fewer grader blade changes and and excellent resistance to "crowning" for applications that require a level grading operation. In addition, ZHONGBO can recommend different grades of cemented carbide snow plow cutting edge according to the environment and weather temperature. Help customers improve work efficiency and service life.

For more details about carbide snowplow blades, welcome to visit our website: www.zhongbocarbide.com.

Hot tags: carbide snowplow blades, advantages of cemented carbide snowplow blades, Carbide cutting edge, tungsten carbide snowplow insert, carbide grader blades, Pick carbide inserts, Double carbide curved blades, tungsten carbide insert, carbide cutting edges, Flat face carbide insert with carbide plate, China, Customized, buy, high quality, manufacturers, suppliers, free sample, factory, made in China